Sidebar

<latex>{\fontsize{16pt}\selectfont \textbf{Functional Use of Soft Skin in Robotics}} </latex>

<latex>{\fontsize{12pt}\selectfont \textbf{Alessandro Simovic}} </latex>

<latex>{\fontsize{10pt}\selectfont \textit{Bachelor Thesis ME}} </latex>

<latex> {\fontsize{12pt}\selectfont \textbf{Abstract} </latex>

Animals and humans in nature rely on soft spring-like elements in their bodies for locomotion, manipulation and tactile sensing. Being efficient in these tasks can be crucial for surviving leading to the assumption that the naturally appearing mechanisms are already highly optimized.

Inspired by nature, nowadays many engineers use soft elements in the design of robotic systems, hoping to improve safety, stability, robustness and efficiency. While soft elements manifest continuously in the field of robotics not much research has been done in relation to the functional use of skin or how the performance of control algorithms is affected in interaction and locomotion.

This thesis connects the intuitive design with existing knowledge on the subject of soft limbs and a study regarding the conception of the human body is conducted. To reinforce the theoretical background a mechanical model is developed allowing to do simulations and gather results for different compositions of the skin or other tissue. In order to do so four different tasks have been created, each with its own performance indicators such as time for completion or energy consumption.

Analysis of the collected data has established that some trade-offs are involved and the engineer has to prioritise certain criteria in order to meet the demands in various areas. For some tasks and especially when a fast actuator is used a well performing and highly efficient system can be consolidated with the right combination of stiffness and damping.

Overall it is shown that proper material parameters can enormously improve stability, performance and energy consumption of the system, even if the passive skin element is only a few centimeters thick.

<latex> {\fontsize{12pt}\selectfont \textbf{Optimization: Example} </latex>

One of the tasks is hopping, split into the two subtasks propulsion and landing. In a first step a LQR-Controller was designed and in a second step good skin properties have been found through computationally intensive iterations. An example of results obtaines through iteration is shown below:

| No Optimization | Optimized Skin |

|---|---|

| Initial guess | Skin properties optimized for a fast landing. Paramters found with parameter sweep. |

<latex> {\fontsize{12pt}\selectfont \textbf{Mechanical Model}} </latex>

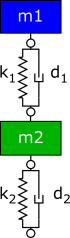

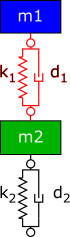

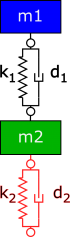

The model used throughout this work is a two mass oscillator with parallel springs and dampers. The inspiration for the concept comes from 1) work.

<latex> {\fontsize{12pt}\selectfont \textbf{Results}} </latex>

The following table gives an idea of how much improvement can been achieved when using the right material properties compared to worst case scenario.

| Hopping | Gripping | Stabilization |

|---|---|---|

| Up to 25% higher jumping height or up to 5 times quicker stabilization after landing | Up to 5 times less overshoot in force | Up to 10 times smaller power flow at upper mass |

<latex> {\fontsize{12pt}\selectfont \textbf{Simulation}} </latex>

The core form the ode solvers provided in Matlab. The solvers are used to integrate a set of differential equations for given initial conditions and for a certain time span. The integration can be interrupted by user-defined events, allowing us to stop the integration if any discontinuity occurs (such as the hopper touching the ground). After a reinitialization of the discontinuous states the integration can continue. The mechanisms of the simulation and the process are described here:

load(options)

load(parameters)

initialize_states(options, parameters)

% A while loop is created which runs the integration until

% the specified end time t_final is reached.

while (time < t_final)

INTEGRATE_ODE()

reinitialize_states()

end

% After the integration is done, the performance is computed

% depending on the active task (specified in options).

compute_performance()

Where the function INTEGRATOR_ODE is defined as follows

function INTEGRATE_ODE(options, states)

update_position()

update_velocity()

% Update controller and other states of same order

update_control_reference()

update_controller()

update_actuator()

update_acceleration()

% Finally an event-manager checks the simulation for discontinuous

% changes, in which case the integration is interrupted.

check_events()

end

<latex> {\fontsize{12pt}\selectfont \textbf{Future Work} </latex>

- In a next step the mechanical model should be validated using a real experimental setup. This would allow to find out if simulated and observed behaviour of the model are congruent, which is important if general conclusions are to be drawn from the computed results.

- There is certainly a lot to learn about the effects of soft skin in various robotic applications. So far we have only covered four distinct scenarios hoping to gain some insight into the effects that different skin properties have. One could develop a multitude of additional tasks, for instance a shock-absorption test in order to investigate the matter further. Eventually walking and running would be of interest as well instead of a vertical hopping motion. Furthermore one should analyse the control bandwidth which is reduced when using soft skin on mechanical actuators.

- Discrete time control has been neglected completely and the existing control algorithms should definitely be tested with a small time delay in place.